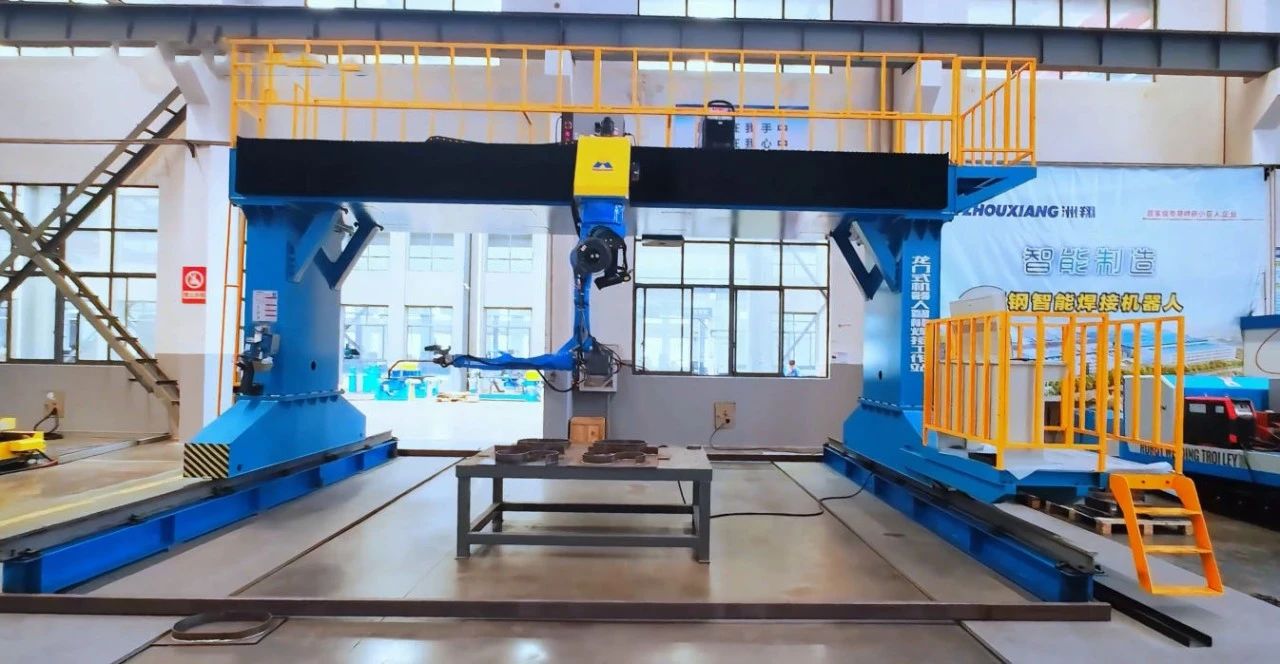

Large Line Scanning, Laser Weld Tracking | Gantry-Type Intelligent Welding Workstation

Sep 14, 2024

Large Line Scanning, Laser Weld Tracking

Gantry-Type Intelligent Welding Workstation

As a key technology for welding process automation, intelligent welding robots represent the direction of welding industry upgrading. By using robots to replace manual welding, the accuracy and efficiency of welding can be significantly improved, while reducing production costs and optimizing the working environment. At present, Zhouxiang welding robots have achieved remarkable application results in many industries such as steel structures, bridges, and ships by virtue of their newly upgraded intelligent welding control systems and other advantages.

In order to further improve the level of intelligent welding of steel structures, Zhouxiang's gantry-type intelligent welding workstation adopts a gantry structure, with a robot inverted under the mobile gantry beam. The gantry walks on the longitudinal track, and the robot arm moves horizontally left and right on the beam. The working range can cover the entire welding unit. The workstation uses the latest Bochu 3800 system, which does not require programming or teaching, nor does it need to import 3D drawings. It directly uses a large line scan camera to scan the workpiece, reverse modeling, and then automatically avoid obstacles and find positions according to the generated model. The computer terminal can also automatically match the corresponding welding process and automatically weld the weld.

Advantages of this workstation

- The non-contact laser vision system does not need to contact the workpiece, can locate the weld at high speed and high precision and track in real time, which greatly simplifies the application of the robot.

- It has the ability to resist arc, smoke, spatter, spot welding and electromagnetic interference, and adapt to various complex welding environments.

- It supports a variety of weld types, including internal fillet welds, spliced welds, lap welds, external fillet welds, external convex welds, etc., to meet different welding needs.

- It is suitable for all welding processes with high precision, fast processing speed and strong anti-interference.

- In the case of workpiece assembly errors, it can ensure the accurate position of the welding gun and improve the welding quality.

- It can realize automatic welding of robots, greatly reduce the labor intensity and the influence of human factors, have good weld consistency, beautiful molding and improve welding efficiency.

- One person can operate multiple robots at the same time, replace welders with general workers, and reduce labor costs.

Zhouxiang gantry intelligent welding workstation has set a benchmark for the intelligent transformation of the welding industry with its high intelligence, high precision, high efficiency, strong adaptability and low cost. With the continuous advancement of technology and the continuous expansion of application scenarios, this intelligent welding workstation will play an important role in more fields and promote the upgrading and development of the entire welding industry.

.jpg)

Zhouxiang Enterprise

Specializes in the production of H-beam light and heavy steel production lines, box beam production lines, horizontal production lines, double-joint welding and straightening automatic lines, steel structure robot intelligent workstations, and various intelligent production lines; including CNC flame plasma cutting machines, fiber laser flatbed cutting machines, laser pipe cutting machines, tube-sheet integrated machines, handheld laser welding machines, H-beam assembly machines, gantry submerged arc welding machines, H-beam straightening machines, shot blasting machines, H-beam assembly welding and straightening integrated machines, welding special machines, auxiliary machines, etc.

Zhouxiang manufacturing, professional quality, high precision, high speed.

Leading technology, stable quality, products are sold well at home and abroad.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Sep 12, 2025

Gao Fenglin: The Rocket's Heart Welder