[Steel Structure Encyclopedia] Introduction To The Uses And Characteristics Of Galvanized Steel Sheets!

Jan 25, 2025

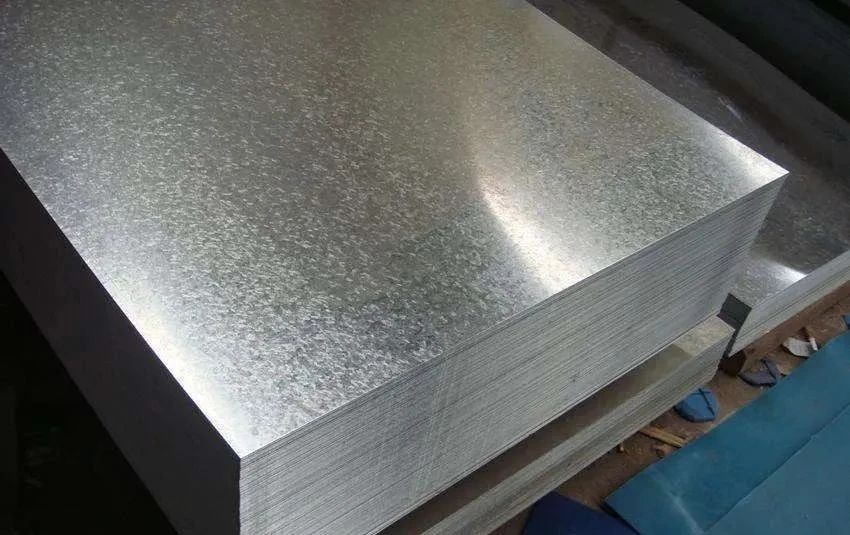

The surface of galvanized steel sheet is smooth, flat and gorgeous with silvery white base color. The special coating structure makes it have excellent corrosion resistance. The normal service life of galvanized steel sheet can reach 25 years, and it has good heat resistance and can be used in high temperature environment of 315℃. The coating has good adhesion with the paint film and has good processing performance. It can be stamped, sheared, welded, etc. The surface conductivity is very good.

The coating composition is composed of 55% aluminum, 43.4% zinc, and 1.6% silicon by weight. The production process of galvanized steel sheet is similar to that of galvanized steel sheet and aluminum sheet, which is a continuous molten coating process. The 55% aluminum-zinc alloy-coated galvanized steel sheet has superior corrosion resistance compared with the galvanized steel sheet of the same thickness when both sides are exposed to the same environment. The 55% aluminum-zinc alloy-coated galvanized steel sheet not only has good corrosion resistance, but also has excellent adhesion and flexibility in color-coated products.

Classification

According to performance, galvanized steel sheets can be divided into galvanized steel G550 and galvanized steel S550. The main difference between galvanized steel G550 and S550 lies in their composition and application areas. G550 galvanized steel sheet mainly consists of 55% aluminum and 43.4% zinc, and also contains 1.6% silicon. It forms a dense quaternary crystal by solidifying at a high temperature of 600℃, and has excellent corrosion resistance. This material is widely used in environments that require high corrosion resistance, such as outdoor exposure tests.

S550 is a light steel keel material, mainly used in building structures. Light steel keels have the characteristics of light weight, good fire resistance, high construction efficiency, and safe and reliable structure. They are often used in the assembly of suspended ceilings and partitions.

Comparison

S550: It has high strength and good toughness. It is widely used in building structures, bridges, automobile manufacturing and other fields. G550: There is less information about the specific chemical composition and mechanical properties of G550, but usually in the grade of structural steel, the number indicates the yield strength, so G550 may also have a higher yield strength.

Application areas

S550: Due to its high strength and good toughness, S550 is widely used in structural applications that require high strength and good toughness, such as building structures, bridges, and automobile manufacturing.

G550: There is less information on the specific application areas of G550, but based on its grade, it may also be suitable for structural applications that require high strength.

Price and market supply

S550: As a common low-alloy high-strength steel, S550 has a relatively stable supply in the market and a relatively reasonable price. G550: There is less information about the market supply and price of G550, but the market price of high-strength steel is usually affected by factors such as supply and demand and raw material costs.

Summary

S550 is more suitable for structural applications that require high strength and good toughness due to its wide application and good market supply.

G550 has less specific information, but its high strength characteristics also make it suitable for similar application scenarios.

When choosing, it is recommended to decide which steel to use based on specific usage requirements, cost budget and market supply.

.jpg)

Zhouxiang Enterprise

Specializes in the production of H-beam light and heavy steel production lines, box beam production lines, horizontal production lines, double-joint welding and straightening automatic lines, steel structure robot intelligent workstations, and various intelligent production lines; including CNC flame plasma cutting machines, fiber laser flatbed cutting machines, laser pipe cutting machines, tube-sheet integrated machines, handheld laser welding machines, H-beam assembly machines, gantry submerged arc welding machines, H-beam straightening machines, shot blasting machines, H-beam assembly welding and straightening integrated machines, welding special machines, auxiliary machines, etc.

Zhouxiang manufacturing, professional quality, high precision, high speed.

Leading technology, stable quality, products are sold well at home and abroad.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Sep 12, 2025

Gao Fenglin: The Rocket's Heart Welder