Self-aligned Welding Rotator GLHZ

Self-aligned welding rotator includes one power and one idle, after loading the work piece, the rollers will auto suit the work piece, no need to adjust the center distance. This welding rotator mainly consists of powered rotator, idle rotator, driving reducer system, control system etc. It is mainly used for longitudinal and circular seam welding of cylinders together with the submerged arc welder.

1.The structure parts of the rotator has the annealing treatment after welding,which can ensure the long-term using performance and service life.

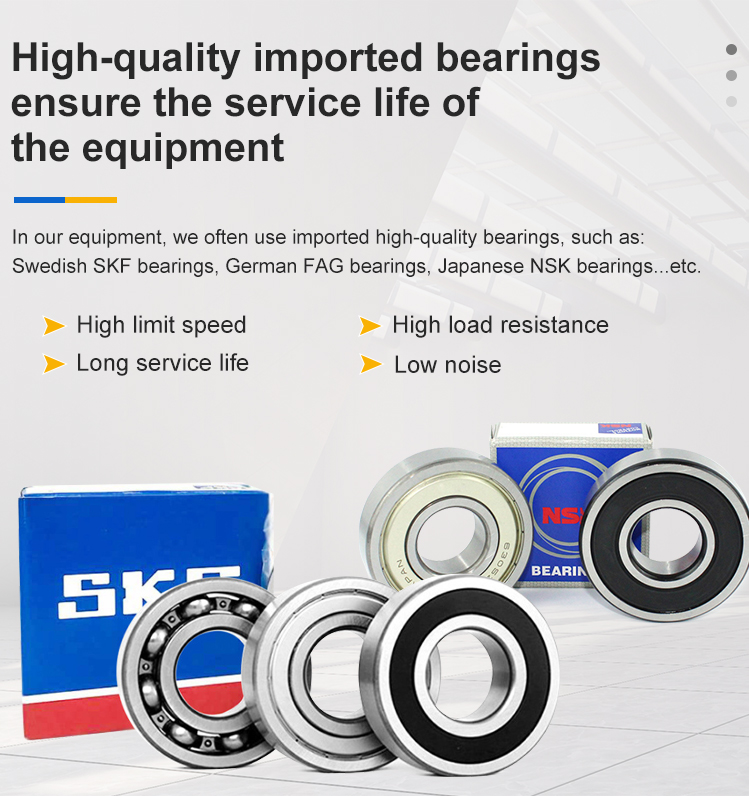

2.The rotator adopts reasonable structure with good rigidity. The mechanical transmission is equipped with dust proof device, as well as good abrasion proof performance.

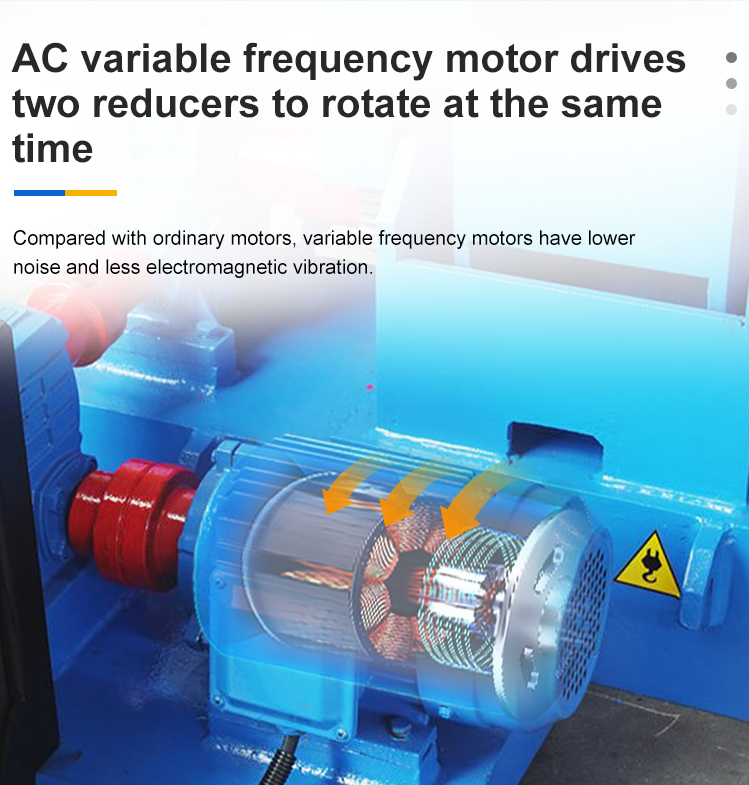

3.The transmission mechanism: motor---multi-step speed adjust----roll, the roller speed adopts frequency speed adjusting.

4.The rollers use rubber casting with abrasion resistance and long service life. The PU roller and metal roller also can be customized according to users’requirement.

5.The four rollers of the rotator are all powered rollers, adopt double driving system. The driving motor adopts AC motor, driving system has the functions of voltage protection and overload protection.

6.Base sliding surface adopts finish machining, mounting and fixing hole is designed on it. By fixing the rotator via holes with different position, then the center distance of rotator will be changed to suit the using requirement of different work-piece.

7.The lubrication system is designed on each motion part of the rotator with refueling device and seal dust-proof device.

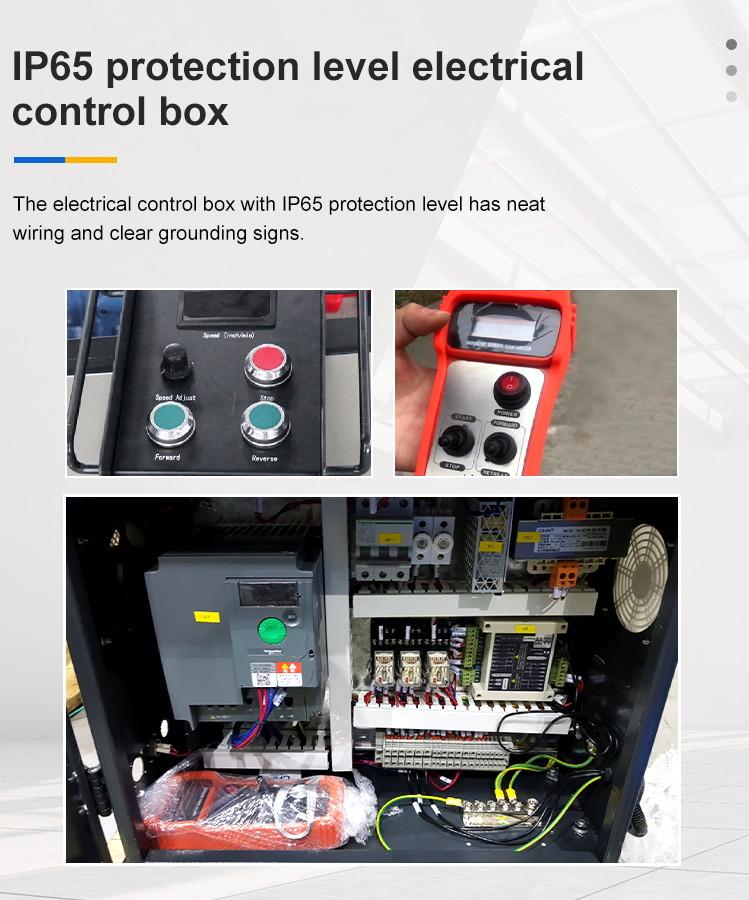

8.All of the operation for rotator can be centralized on one remote control panel with E-stop button on it.

9.The base of motor has enough rigidity. When rated loading, the down-warp deformation won’t affect the normal using. At the same time, the rotator has overload capacity within some limits .

Specifications:

|

Spec. |

Max. load weight-kg |

Suitable diameter of vessel(mm) |

Dia. and width of the wheel |

Roller linear speed-m/h |

Power of motor-kw |

|

|

PU rollers- mm |

Metal rollers- mm |

|||||

|

GLHZ-5 |

5000 |

φ250-φ2300 |

φ250*140 |

|

6-60 |

0.75 |

|

GLHZ-10 |

10000 |

φ320-φ2800 |

φ300*170 |

|

6-60 |

1.1 |

|

GLHZ-20 |

20000 |

φ500-φ3500 |

φ350*180 |

|

6-60 |

2.2 |

|

GLHZ-40 |

40000 |

φ600-φ4200 |

φ400*200 |

|

6-60 |

3 |

|

GLHZ-60 |

60000 |

φ750-φ4800 |

φ450*220 |

|

6-60 |

4 |

|

GLHZ-80 |

80000 |

φ850-φ5000 |

φ500*240 |

|

6-60 |

4 |

|

GLHZ-100 |

100000 |

φ1000-φ5500 |

φ500*260 |

|

6-60 |

5.5 |

|

GLHZ-150 |

150000 |

φ1100-φ6000 |

|

φ600*280 |

6-60 |

7.5 |

|

GLHZ-250 |

250000 |

φ1200-φ7000 |

|

φ700*300 |

6-60 |

2*5.5 |

|

GLHZ-500 |

500000 |

φ1800-φ8000 |

|

φ850*350 |

6-60 |

2*7.5 |