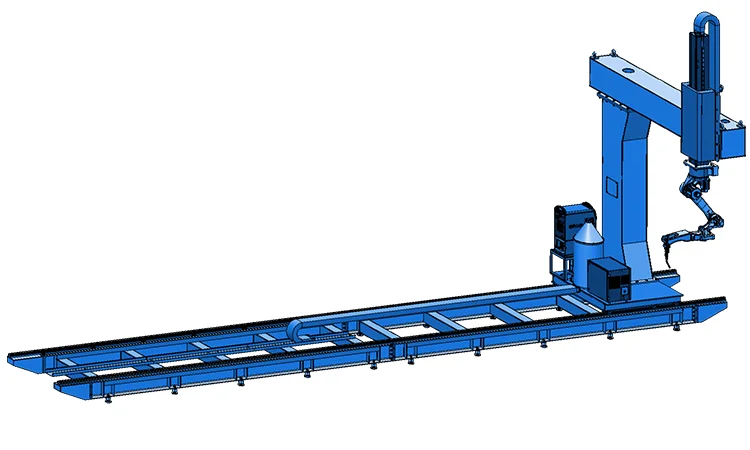

Cantilever Robot Welding Workstation

The cantilever robot intelligent welding workstation is equipped with the Friendess teaching-free welding system and the Friendess wide-angle weld tracker. It can directly import the 3D model files of Tekla, SOLIDWORKS or UG, directly match the welding process parameters, automatically identify the accurate position of the weld and generate the best Welding process. The robot is equipped with an automatic gun washing device. The track length can be customized according to the product. The user determines the required track length according to the length of the workpiece, making the application more flexible.

At present, it is mainly used for the welding of H beam steelordinary reinforcement plate, transverse reinforcement plate, column bottom plate, purlin support plate, corbel and other structures.

The advantage of the cantilever type is that the workpieces can belifted to the workstation in batches, saving lifting time.

|

Robot

|

MR12-2010

|

|

Welder

|

Aotai/Megmeet

|

|

Welding gun

|

TRM water-cooled extended welding gun

|

|

Control system

|

Friendess teaching-free welding system

|

|

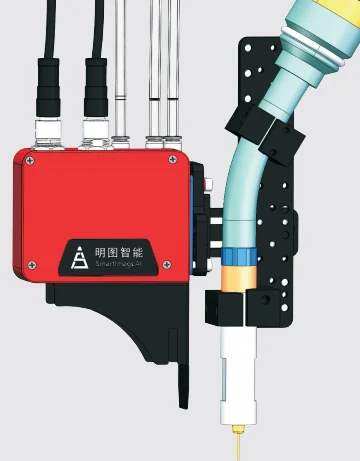

Vision system

|

Friendess large viewing distance sea m finder

|

|

Rail

|

12m(length can be customized)

|

|

Application scenario

|

secondary processing for steel structure

|

|

Machine spec

|

(7 axis)ZX-XRYH100(8 axis) ZX-XRYHSW100

|

|

Total power

|

(7 axis) Robot 10KVA +welder 31KVA(8 axis) Robot 13KVA+welder31KVA

|

|

Max. operating range

|

(7 axis)10m×1.3m×0.4m(12mground rail)

(8 axis)10m×1.3m×1.2m(12m ground rail)

|

|

Average welding efficiency

|

0.3-0.5m/min(different weldingprocess, different speed)

|

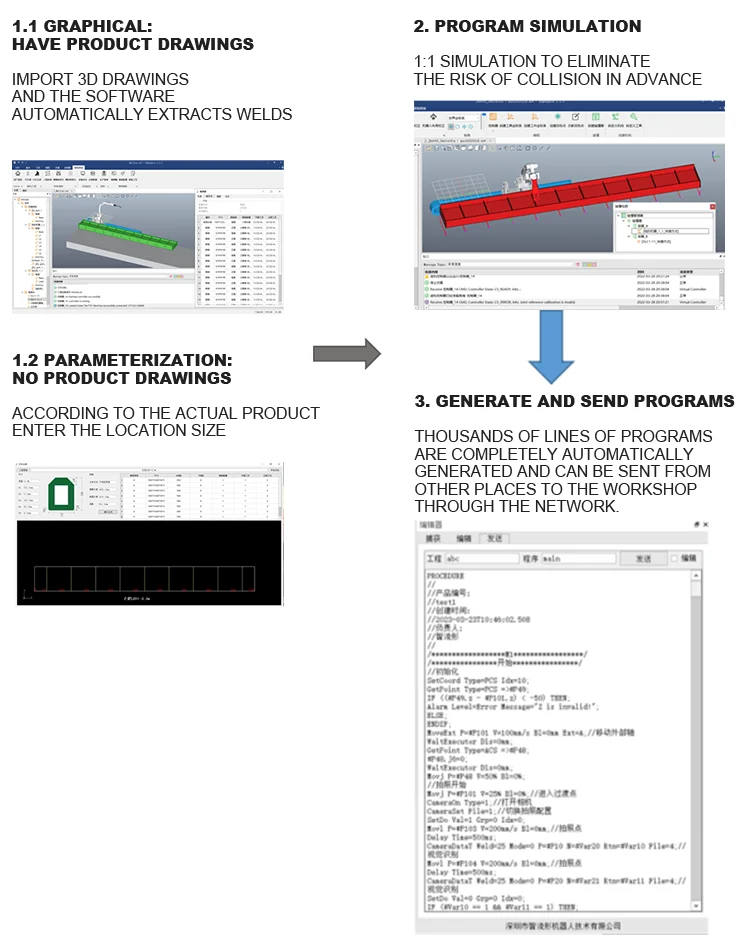

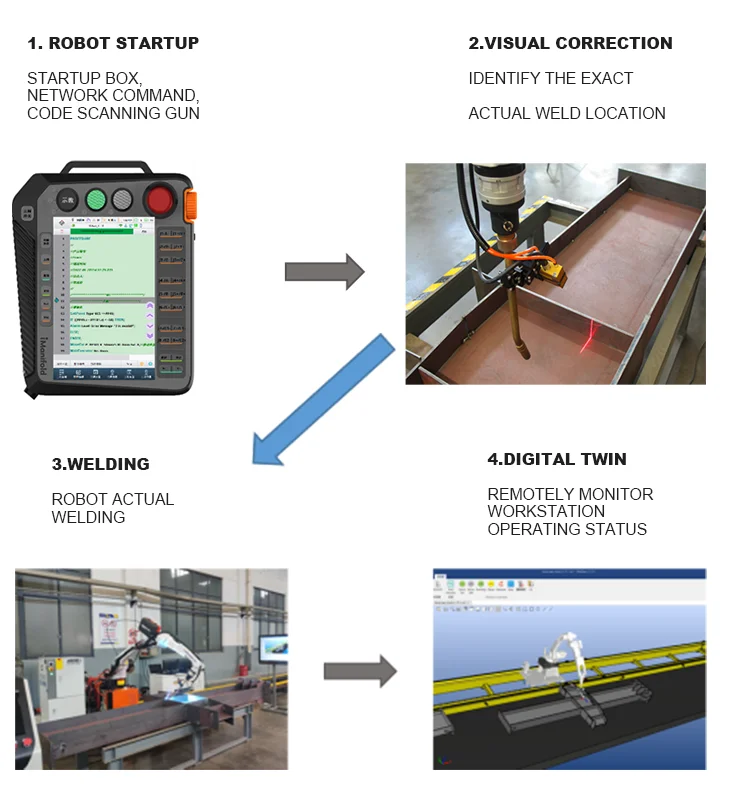

Robot Operation Process

the welding gun during robot welding, automatically cut wires, and protect the welding gun nozzle and contact tip, extending the service life of the welding gun and saving money. Reduce consumable costs, maintain good welding quality, and improve welding

efficiency. Simple operation and easy to use.Advantages of gun cleaning stations: 1. The gun clearing time is short and the system

availability is high. 2. Automatically complete the gun cleaning process without manual operation. 3. Prevent quality problems

caused by contamination during welding. 4. Equipped with robot TCP calibration needle.

Robot welding software