Ground Rail Type Welding Robot

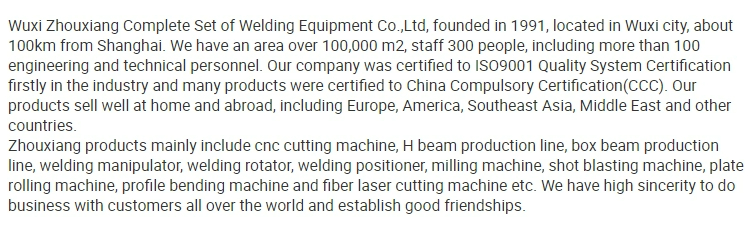

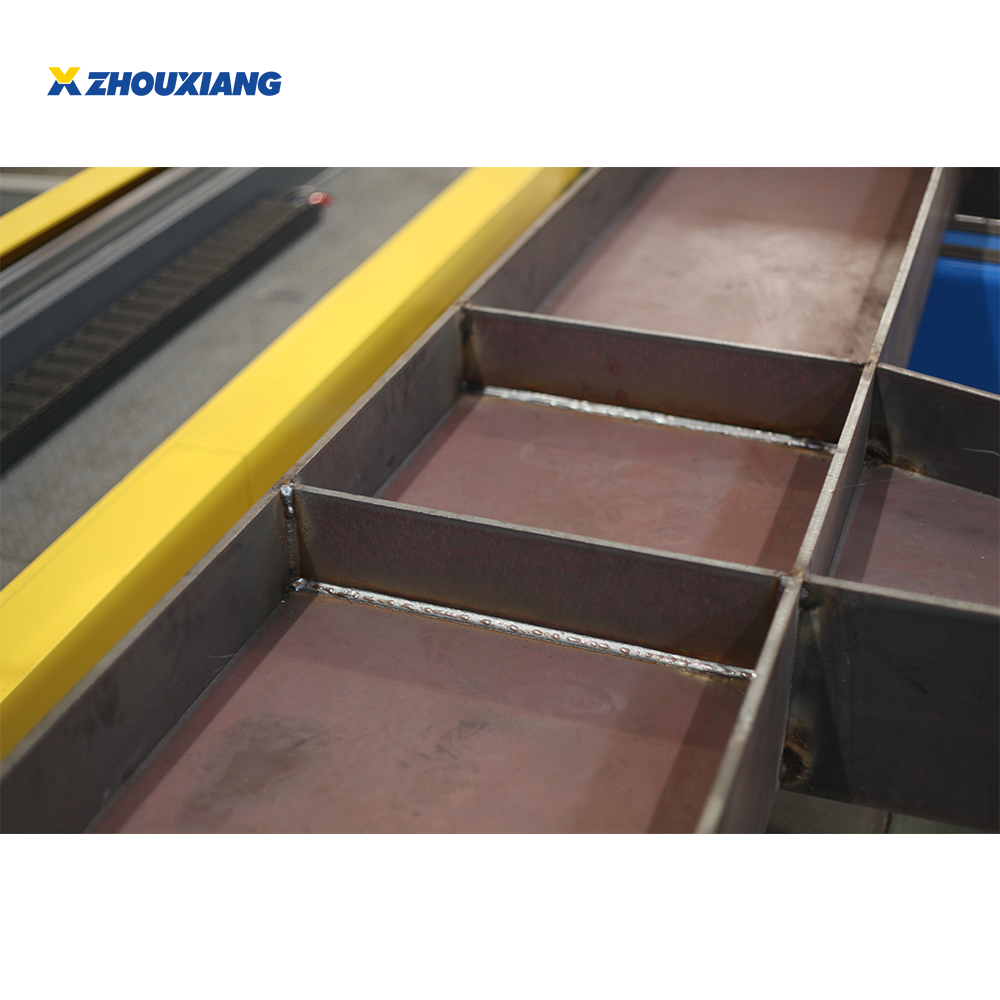

H-Beam Ground Rail Welding Robot Suitable for gusset plates, corbel parts, small structural parts, etc. It can currently be used in H-Beam main beams and secondary beams of steel structures, small and medium-sized plate units of ship bridges, equipment H-Beam columns,

equipment platform beams and other structures.

Product Description

The ground rail type welding robot is equipped with intelligent Friendess teaching-free welding system and large visual distance seam finder. It can directly import the 3D model files of Tekla, SolidWorks or UG, directly match the welding process parameters, automatically indentify the precise weld position and generate the best optimized welding process for welding.

The ground rail type walking axis increases the adaptability of length direction. The robot can link with the ground rail to weld longer seam at a time, and the workstation can work on the left and right sides of the rail. It is mainly used for the welding of H beam rib plates, column base plates, purlin support plates, corbels and other structures.

| Robot | 1 set of Zhouxiang robot |

| Optional welding power source | Aotai welding machine and its accessories or Megmeet welding machine and its accessories |

| Welding system | Zhouxiang teaching-free offline programming welding software, Mingtu line laser tracking |

| Applicable scenarios | Suitable for gusset plates, corbel parts, small structural parts, etc. It can currently be used in H-shaped main beams and secondary beams of steel structures, small and medium-sized plate units of ship bridges, equipment H-shaped steel columns, equipment platform beams and other structures. |

| Gun cleaning system | SC220A gun cleaning system |

| Ground rail length | 6 meters (optional according to user) |

Robot Operation Process

Robot Introduction

The robot wrist adopts a hollow structure, and the surrounding forearms and five-axis wrists are equipped with built-in wiring channels. The welding gun can rotate 360° without tangling the lines. Compared with the traditional external structure welding gun, the spatial movement range is larger and the operation is more flexible, achieving Optimization of performance and energy efficiency. Application areas: special for welding (gas shielding, argon arc, laser, aluminum, stainless steel, carbon steel)

| Optional robot models | ZXR12-2010 | ZXR10W-1440-D |

| Number of axes | 6 axes | 6 axes |

| Movement radius | 2010mm | 1440mm |

| Payload | 12KG | 10KG |

| Protection level | J1, J2 axis IP56 (J3, J4, J5, J6 axis IP67) | J1, J2 axis IP56 (J3, J4, J5, J6 axis IP67) |

| Installation method | floor-standing/bracket type/upside-down type | floor-standing/bracket type/upside-down type |

| Power capacity | 4.5KVA | 4.5KVA |

| Input/output signal | standard 16 in/16 out 24VDC | standard 16 in/16 out 24VDC |

| Robot weight | 313KG | 210KG |

| Repeat positioning accuracy | ±0.05 | ±0.05 |

Gun Clearing System

Advantages of gun cleaning stations: 1. The gun clearing time is short and the system availability is high. 2. Automatically complete the gun cleaning process without manual operation. 3. Prevent quality problems caused by contamination during welding. 4. Equipped with robot TCP calibration needle.

Robot welding software

The software can automatically extract welds from drawings without weld marking, reducing the workload of manual participation. With the high-performance 3D engine and robot controller, the automatically created points are simulated and verified to avoid collisions in actual work.

Advantage

6.Digital twin technology can display on-site robot trajectory, welding voltage, current, speed and other production information in real time.

Software Operation Process